| ASME B16.9: Carbon Steel, Stainless Steel, Alloy Steel |

| EN 10253-1: Carbon Steel, Stainless Steel, Alloy Steel |

| JIS B2311: Carbon Steel, Stainless Steel, Alloy Steel |

| DIN 2605: Carbon Steel, Stainless Steel, Alloy Steel |

| GB/T 12459: Carbon Steel, Stainless Steel, Alloy Steel |

| ASME B16.9: Factory-Made Wrought Butt-Welding Fittings | Materials: Carbon Steel, Stainless Steel, Alloy Steel |

| EN 10253-1: Butt-Welding Pipe Fittings - Part 1: Wrought Carbon Steel for General Use and Without Specific Inspection Requirements | Materials: Carbon Steel, Stainless Steel, Alloy Steel |

| JIS B2311: Steel Butt-Welding Pipe Fittings for Ordinary Use | Materials: Carbon Steel, Stainless Steel, Alloy Steel |

| DIN 2605: Steel Butt-Welding Pipe Fittings: Elbows and Bends with Reduced Pressure Factor | Materials: Carbon Steel, Stainless Steel, Alloy Steel |

| GB/T 12459: Steel Butt-Welding Seamless Pipe Fittings | Materials: Carbon Steel, Stainless Steel, Alloy Steel |

Reducers play a transformative role in pipeline configuration, facilitating smooth transitions between pipes of varying sizes. This optimization enhances overall system efficiency and functionality. Elbow: The steel pipe elbow holds a pivotal role within piping systems, facilitating changes in fluid flow direction. It finds application in connecting pipes of either identical or varying nominal diameters, effectively redirecting the flow along desired trajectories. Elbows are categorized based on the degree of fluid direction alteration they introduce to pipelines. The commonly encountered angles include 45 degrees, 90 degrees, and 180 degrees. For specialized applications, angles like 60 degrees and 120 degrees come into play. Elbows fall into distinct classifications based on their radius relative to pipe diameter. A Short Radius Elbow (SR elbow) features a radius equal to the pipe diameter, making it suitable for low-pressure, low-speed pipelines, or confined spaces where clearance is at a premium. Conversely, a Long Radius Elbow (LR elbow), with a radius 1.5 times the pipe diameter, finds application in high-pressure and high-flow-rate pipelines. Elbows can be grouped according to their pipe connection methods—Butt Welded Elbow, Socket Welded Elbow, and Threaded Elbow. These variations offer versatility based on the joint type employed. Material-wise, elbows are crafted from stainless steel, carbon steel, or alloy steel, adapting to specific valve body requirements.

Reducers play a transformative role in pipeline configuration, facilitating smooth transitions between pipes of varying sizes. This optimization enhances overall system efficiency and functionality. Elbow: The steel pipe elbow holds a pivotal role within piping systems, facilitating changes in fluid flow direction. It finds application in connecting pipes of either identical or varying nominal diameters, effectively redirecting the flow along desired trajectories. Elbows are categorized based on the degree of fluid direction alteration they introduce to pipelines. The commonly encountered angles include 45 degrees, 90 degrees, and 180 degrees. For specialized applications, angles like 60 degrees and 120 degrees come into play. Elbows fall into distinct classifications based on their radius relative to pipe diameter. A Short Radius Elbow (SR elbow) features a radius equal to the pipe diameter, making it suitable for low-pressure, low-speed pipelines, or confined spaces where clearance is at a premium. Conversely, a Long Radius Elbow (LR elbow), with a radius 1.5 times the pipe diameter, finds application in high-pressure and high-flow-rate pipelines. Elbows can be grouped according to their pipe connection methods—Butt Welded Elbow, Socket Welded Elbow, and Threaded Elbow. These variations offer versatility based on the joint type employed. Material-wise, elbows are crafted from stainless steel, carbon steel, or alloy steel, adapting to specific valve body requirements.

Types of Steel Pipe Tee: ● Based on Branch Diameters and Functions: ● Equal Tee ● Reducing Tee (Reducer Tee) Based on Connection Types: ● Butt Weld Tee ● Socket Weld Tee ● Threaded Tee Based on Material Types: ● Carbon Steel Pipe Tee ● Alloy Steel Tee ● Stainless Steel Tee Applications of Steel Pipe Tee: ● Steel pipe tees are versatile fittings that find applications in various industries due to their ability to connect and direct flows in different directions. Some common applications include: ● Oil and Gas Transmissions: Tees are used to branch off pipelines for transporting oil and gas. ● Petroleum and Oil Refining: In refineries, tees help manage the flow of different products during refining processes. ● Water Treatment Systems: Tees are used in water treatment plants to control the flow of water and chemicals. ● Chemical Industries: Tees play a role in chemical processing by directing the flow of different chemicals and substances. ● Sanitary Tubing: In food, pharmaceutical, and other industries, sanitary tubing tees help maintain hygienic conditions in fluid transport. ● Power Stations: Tees are used in power generation and distribution systems. ● Machines and Equipment: Tees are integrated into various industrial machinery and equipment for fluid management. ● Heat Exchangers: Tees are used in heat exchanger systems to control the flow of hot and cold fluids. Steel pipe tees are essential components in many systems, providing flexibility and control over the distribution and direction of fluids. The choice of material and type of tee depends on factors such as the type of fluid being transported, pressure, temperature, and the specific requirements of the application.Pipe Elbow dimensions are covered in ASME B16.9. Refer to the table given below for the dimension of the elbow size 1/2″ to 48″.

Types of Steel Pipe Tee: ● Based on Branch Diameters and Functions: ● Equal Tee ● Reducing Tee (Reducer Tee) Based on Connection Types: ● Butt Weld Tee ● Socket Weld Tee ● Threaded Tee Based on Material Types: ● Carbon Steel Pipe Tee ● Alloy Steel Tee ● Stainless Steel Tee Applications of Steel Pipe Tee: ● Steel pipe tees are versatile fittings that find applications in various industries due to their ability to connect and direct flows in different directions. Some common applications include: ● Oil and Gas Transmissions: Tees are used to branch off pipelines for transporting oil and gas. ● Petroleum and Oil Refining: In refineries, tees help manage the flow of different products during refining processes. ● Water Treatment Systems: Tees are used in water treatment plants to control the flow of water and chemicals. ● Chemical Industries: Tees play a role in chemical processing by directing the flow of different chemicals and substances. ● Sanitary Tubing: In food, pharmaceutical, and other industries, sanitary tubing tees help maintain hygienic conditions in fluid transport. ● Power Stations: Tees are used in power generation and distribution systems. ● Machines and Equipment: Tees are integrated into various industrial machinery and equipment for fluid management. ● Heat Exchangers: Tees are used in heat exchanger systems to control the flow of hot and cold fluids. Steel pipe tees are essential components in many systems, providing flexibility and control over the distribution and direction of fluids. The choice of material and type of tee depends on factors such as the type of fluid being transported, pressure, temperature, and the specific requirements of the application.Pipe Elbow dimensions are covered in ASME B16.9. Refer to the table given below for the dimension of the elbow size 1/2″ to 48″.

| NOMINAL PIPE SIZE | OUTSIDE DIAMETER | CENTER TO END | ||

| Inch. | OD | A | B | C |

| 1/2 | 21.3 | 38 | 16 | – |

| 3/4 | 26.7 | 38 | 19 | – |

| 1 | 33.4 | 38 | 22 | 25 |

| 1 1/4 | 42.2 | 48 | 25 | 32 |

| 1 1/2 | 48.3 | 57 | 29 | 38 |

| 2 | 60.3 | 76 | 35 | 51 |

| 2 1/2 | 73 | 95 | 44 | 64 |

| 3 | 88.9 | 114 | 51 | 76 |

| 3 1/2 | 101.6 | 133 | 57 | 89 |

| 4 | 114.3 | 152 | 64 | 102 |

| 5 | 141.3 | 190 | 79 | 127 |

| 6 | 168.3 | 229 | 95 | 152 |

| 8 | 219.1 | 305 | 127 | 203 |

| 10 | 273.1 | 381 | 159 | 254 |

| 12 | 323.9 | 457 | 190 | 305 |

| 14 | 355.6 | 533 | 222 | 356 |

| 16 | 406.4 | 610 | 254 | 406 |

| 18 | 457.2 | 686 | 286 | 457 |

| 20 | 508 | 762 | 318 | 508 |

| 22 | 559 | 838 | 343 | 559 |

| 24 | 610 | 914 | 381 | 610 |

| 26 | 660 | 991 | 406 | 660 |

| 28 | 711 | 1067 | 438 | 711 |

| 30 | 762 | 1143 | 470 | 762 |

| 32 | 813 | 1219 | 502 | 813 |

| 34 | 864 | 1295 | 533 | 864 |

| 36 | 914 | 1372 | 565 | 914 |

| 38 | 965 | 1448 | 600 | 965 |

| 40 | 1016 | 1524 | 632 | 1016 |

| 42 | 1067 | 1600 | 660 | 1067 |

| 44 | 1118 | 1676 | 695 | 1118 |

| 46 | 1168 | 1753 | 727 | 1168 |

| 48 | 1219 | 1829 | 759 | 1219 |

| All Dimensions are in mm | ||||

| NOMINAL PIPE SIZE | ALL FITTINGS | ALL FITTINGS | ALL FITTINGS | ELBOWS AND TEES | 180 DEG RETURN BENDS | 180 DEG RETURN BENDS | 180 DEG RETURN BENDS | REDUCERS |

CAPS |

| NPS | O.D. at Bevel (1), (2) | I.D. at End (1), (3), (4) | Wall Thickness (3) | Centre-to-End Dimension A,B,C,M | Centre-to-Centre O | Back-to-Face K | Alignment of Ends U | Overall Length H | Overall Length E |

| ½ to 2½ | 0.06 -0.03 | 0.03 | Not less than 87.5% of nominal thickness | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| 3 to 3 ½ | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 4 | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 5 to 8 | 0.09 -0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.25 | |

| 10 to 18 | 0.16 -0.12 | 0.12 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| 20 to 24 | 0.25 -0.19 | 0.19 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| 26 to 30 | 0.25 -0.19 | 0.19 | 0.12 | … | … | … | 0.19 | 0.38 | |

| 32 to 48 | 0.25 -0.19 | 0.19 | 0.19 | … | … | … | 0.19 | 0.38 |

| NOMINAL PIPE SIZE NPS | ANGULARITY TOLERANCES | ANGULARITY TOLERANCES | ALL DIMENSIONS ARE GIVEN IN INCHES. TOLERANCES ARE EQUAL PLUS AND MINUS EXCEPT AS NOTED. |

| Off Angle Q | Off Plane P | (1) Out-of-round is the sum of absolute values of plus and minus tolerance. (2) This tolerance may not apply in localized areas of formed fittings where increased wall thickness is required to meet design requirements of ASME B16.9. (3) The inside diameter and the nominal wall thicknesses at ends are to be specified by the purchaser. (4) Unless otherwise specified by the purchaser, these tolerances apply to the nominal inside diameter, which equals the difference between the nominal outside diameter and twice the nominal wall thickness. | |

| ½ to 4 | 0.03 | 0.06 | |

| 5 to 8 | 0.06 | 0.12 | |

| 10 to 12 | 0.09 | 0.19 | |

| 14 to 16 | 0.09 | 0.25 | |

| 18 to 24 | 0.12 | 0.38 | |

| 26 to 30 | 0.19 | 0.38 | |

| 32 to 42 | 0.19 | 0.50 | |

| 44 to 48 | 0.18 | 0.75 |

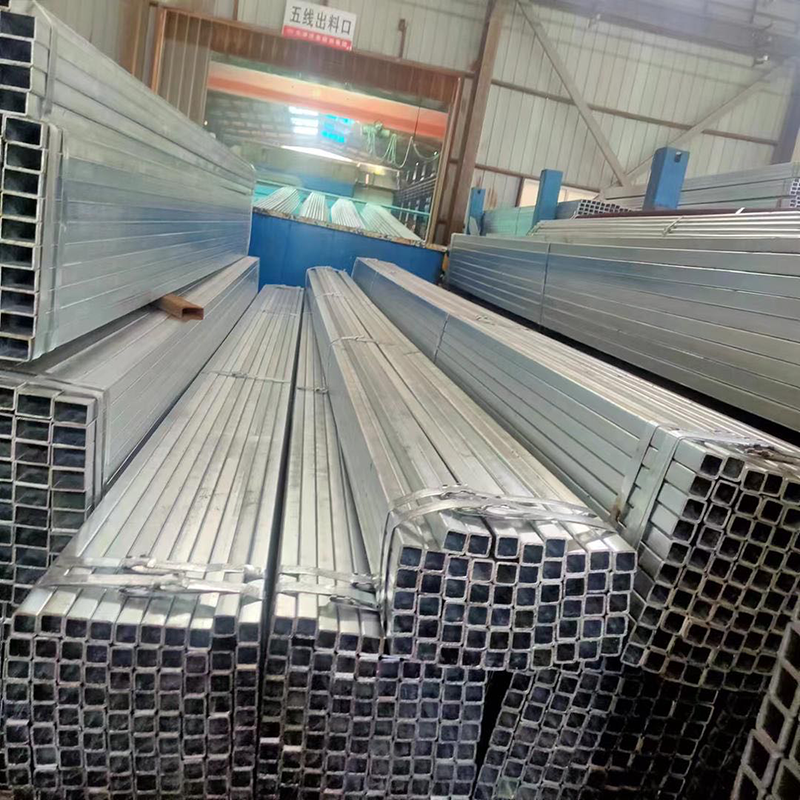

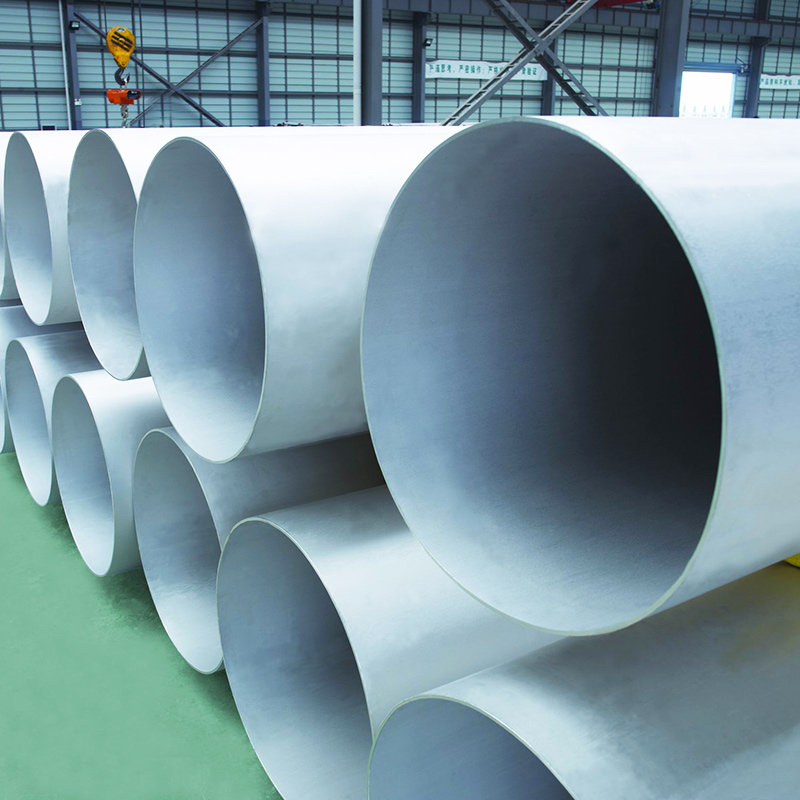

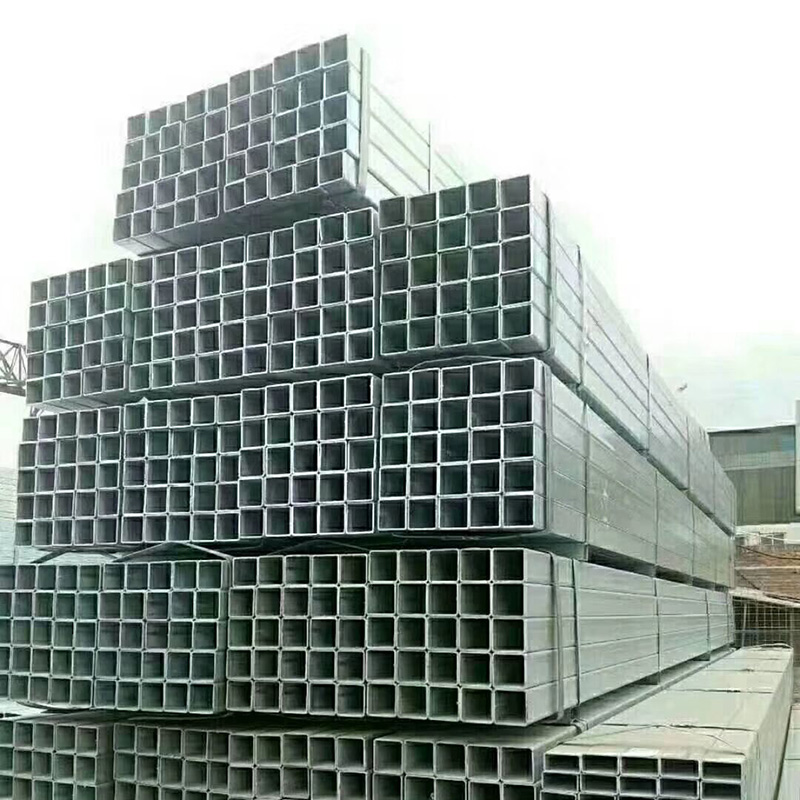

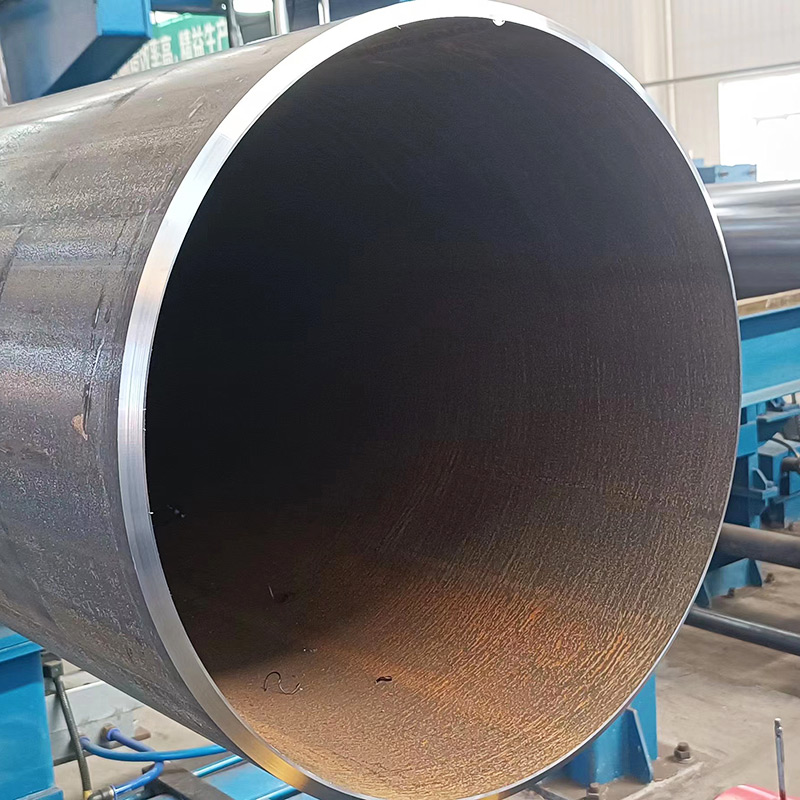

● Support and Anchoring ● Temperature Control ● Hygiene and Sterility ● Safety ● Aesthetic and Environmental Considerations● Connection ● Directional Control ● Flow Regulation ● Media Separation ● Fluid Mixing In summary, pipe fittings are indispensable components that enable the efficient, safe, and controlled transport of fluids and gases across a wide range of industries. Their diverse applications contribute to the reliability, performance, and safety of fluid handling systems in countless settings.At Womic Steel, we understand the importance of secure packaging and reliable shipping when it comes to delivering our high-quality pipe fittings to your doorstep. Here's an overview of our packaging and shipping procedures for your reference: Packaging: Our pipe fittings are carefully packaged to ensure they reach you in perfect condition, ready for your industrial or commercial needs. Our packaging process includes the following key steps: ● Quality Inspection: Before packaging, all pipe fittings undergo a thorough quality inspection to confirm they meet our stringent standards for performance and integrity. ● Protective Coating: Depending on the type of material and application, our fittings may receive a protective coating to prevent corrosion and damage during transportation. ● Secure Bundling: Fittings are bundled together securely, ensuring they remain stable and protected throughout the shipping process. ● Labeling and Documentation: Each package is clearly labeled with essential information, including product specifications, quantity, and any special handling instructions. Relevant documentation, such as certificates of compliance, is also included. ● Custom Packaging: We can accommodate special packaging requests based on your unique requirements, ensuring your fittings are prepared exactly as needed. Shipping: We collaborate with reputable shipping partners to guarantee reliable and timely delivery to your specified destination.Our logistics team optimizes shipping routes to minimize transit times and reduce the risk of delays.For international shipments, we handle all necessary customs documentation and compliance to facilitate smooth customs clearance.We offer flexible shipping options, including expedited shipping for urgent requirements.

● Support and Anchoring ● Temperature Control ● Hygiene and Sterility ● Safety ● Aesthetic and Environmental Considerations● Connection ● Directional Control ● Flow Regulation ● Media Separation ● Fluid Mixing In summary, pipe fittings are indispensable components that enable the efficient, safe, and controlled transport of fluids and gases across a wide range of industries. Their diverse applications contribute to the reliability, performance, and safety of fluid handling systems in countless settings.At Womic Steel, we understand the importance of secure packaging and reliable shipping when it comes to delivering our high-quality pipe fittings to your doorstep. Here's an overview of our packaging and shipping procedures for your reference: Packaging: Our pipe fittings are carefully packaged to ensure they reach you in perfect condition, ready for your industrial or commercial needs. Our packaging process includes the following key steps: ● Quality Inspection: Before packaging, all pipe fittings undergo a thorough quality inspection to confirm they meet our stringent standards for performance and integrity. ● Protective Coating: Depending on the type of material and application, our fittings may receive a protective coating to prevent corrosion and damage during transportation. ● Secure Bundling: Fittings are bundled together securely, ensuring they remain stable and protected throughout the shipping process. ● Labeling and Documentation: Each package is clearly labeled with essential information, including product specifications, quantity, and any special handling instructions. Relevant documentation, such as certificates of compliance, is also included. ● Custom Packaging: We can accommodate special packaging requests based on your unique requirements, ensuring your fittings are prepared exactly as needed. Shipping: We collaborate with reputable shipping partners to guarantee reliable and timely delivery to your specified destination.Our logistics team optimizes shipping routes to minimize transit times and reduce the risk of delays.For international shipments, we handle all necessary customs documentation and compliance to facilitate smooth customs clearance.We offer flexible shipping options, including expedited shipping for urgent requirements. Tee:A steel pipe cap, also referred to as a steel plug, is a fitting used to cover the end of a pipe. It can be welded to the pipe's end or attached to the external thread of the pipe. Steel pipe caps serve the purpose of covering and protecting pipe fittings. These caps come in different shapes, including hemispherical, elliptical, dish, and spherical caps. Shapes of Convex Caps: ● Hemispherical Cap ● Elliptical Cap ● Dish Cap ● Spherical Cap Connection Treatments: Caps are used to cut off transitions and connections in pipes. The choice of connection treatment depends on the specific requirements of the application: ● Butt Weld Connection ● Socket Weld Connection ● Threaded Connection Applications: End caps have a wide range of applications across industries such as chemicals, construction, paper, cement, and shipbuilding. They are particularly useful for connecting pipes of different diameters and providing a protective barrier to the pipe's end. Types of Steel Pipe Cap: Connection Types: ● Butt Weld Cap ● Socket Weld Cap ● Material Types: ● Carbon Steel Pipe Cap ● Stainless Steel Cap ● Alloy Steel CapA steel pipe bend is a type of pipe fitting used to change the direction of a pipeline. While similar to a pipe elbow, a pipe bend is longer and is typically manufactured for specific requirements. Pipe bends come in various dimensions, with different degrees of curvature, to accommodate different turning angles in pipelines. Bend Types and Efficiency: 3D Bend: A bend with a radius three times the nominal pipe diameter. It is commonly used in long pipelines due to its relatively gentle curvature and efficient directional change. 5D Bend: This bend has a radius five times the nominal pipe diameter. It provides a smoother change in direction, making it suitable for extended pipelines while maintaining fluid flow efficiency. Compensating for Degree Changes: 6D and 8D Bend: These bends, with radii six times and eight times the nominal pipe diameter respectively, are used to compensate for small degree changes in the pipeline direction. They ensure a gradual transition without disrupting flow. Steel pipe bends are vital components in piping systems, allowing for directional changes without causing excessive turbulence or resistance in fluid flow. The choice of bend type depends on the specific requirements of the pipeline, including the degree of change in direction, available space, and the need to maintain efficient flow characteristics.

Tee:A steel pipe cap, also referred to as a steel plug, is a fitting used to cover the end of a pipe. It can be welded to the pipe's end or attached to the external thread of the pipe. Steel pipe caps serve the purpose of covering and protecting pipe fittings. These caps come in different shapes, including hemispherical, elliptical, dish, and spherical caps. Shapes of Convex Caps: ● Hemispherical Cap ● Elliptical Cap ● Dish Cap ● Spherical Cap Connection Treatments: Caps are used to cut off transitions and connections in pipes. The choice of connection treatment depends on the specific requirements of the application: ● Butt Weld Connection ● Socket Weld Connection ● Threaded Connection Applications: End caps have a wide range of applications across industries such as chemicals, construction, paper, cement, and shipbuilding. They are particularly useful for connecting pipes of different diameters and providing a protective barrier to the pipe's end. Types of Steel Pipe Cap: Connection Types: ● Butt Weld Cap ● Socket Weld Cap ● Material Types: ● Carbon Steel Pipe Cap ● Stainless Steel Cap ● Alloy Steel CapA steel pipe bend is a type of pipe fitting used to change the direction of a pipeline. While similar to a pipe elbow, a pipe bend is longer and is typically manufactured for specific requirements. Pipe bends come in various dimensions, with different degrees of curvature, to accommodate different turning angles in pipelines. Bend Types and Efficiency: 3D Bend: A bend with a radius three times the nominal pipe diameter. It is commonly used in long pipelines due to its relatively gentle curvature and efficient directional change. 5D Bend: This bend has a radius five times the nominal pipe diameter. It provides a smoother change in direction, making it suitable for extended pipelines while maintaining fluid flow efficiency. Compensating for Degree Changes: 6D and 8D Bend: These bends, with radii six times and eight times the nominal pipe diameter respectively, are used to compensate for small degree changes in the pipeline direction. They ensure a gradual transition without disrupting flow. Steel pipe bends are vital components in piping systems, allowing for directional changes without causing excessive turbulence or resistance in fluid flow. The choice of bend type depends on the specific requirements of the pipeline, including the degree of change in direction, available space, and the need to maintain efficient flow characteristics.